Understanding The Importance Of Preforming In Manufacturing Processes

In the world of manufacturing, the process of preforming plays a crucial role in determining the quality of the final product. Understanding the significance of preforming is key to ensuring a successful manufacturing process. This article delves into the importance of preforming in manufacturing and why it is essential for achieving high-quality end products. Whether you are a seasoned professional or a newcomer to the industry, this article will provide valuable insights into the role of preforming in manufacturing processes.

- The Role of Preforming in Manufacturing

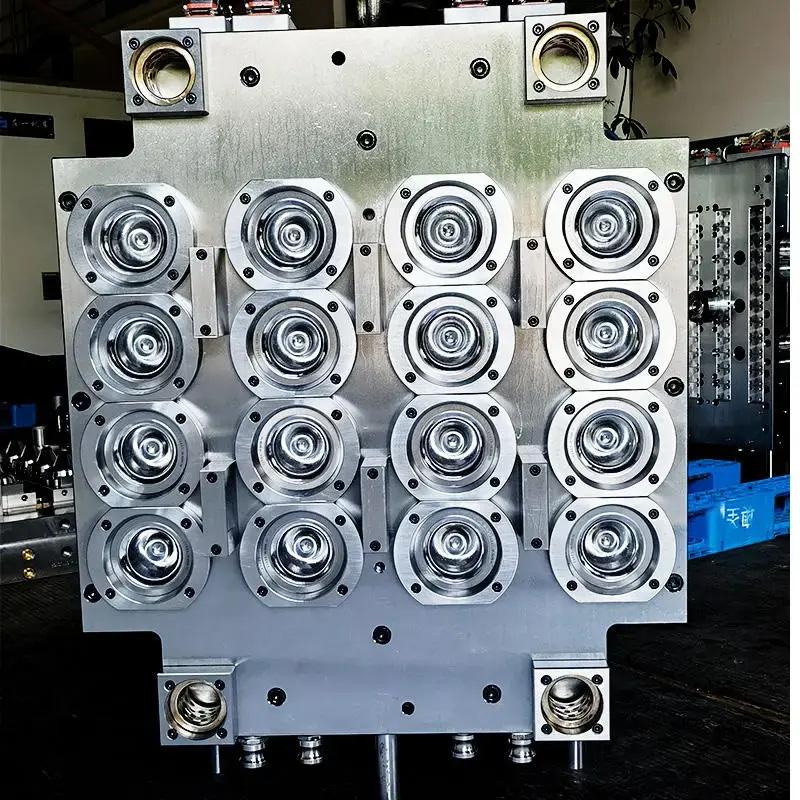

Preforming is a crucial stage in the manufacturing process that holds significant importance in shaping the final product. It involves the shaping of a material before it is further processed through techniques such as molding or casting. This preliminary shaping process is essential in achieving the desired properties and characteristics of the final product. In this article, we will delve deeper into the role of preforming in manufacturing processes, its importance, and the techniques involved.

One of the key aspects of preforming is its ability to enhance the material's structural integrity. By shaping the material before it undergoes further processing, it reduces the likelihood of stress concentrations and improves the overall strength of the final product. This is particularly important in industries such as aerospace, automotive, and engineering where structural integrity is of utmost importance. Preforming also allows for the incorporation of reinforcements such as fibers or fillers, further enhancing the mechanical properties of the material.

Moreover, preforming plays a crucial role in achieving uniformity and consistency in the final product. By shaping the material in its preliminary stage, it ensures that the material maintains a consistent thickness and density throughout, reducing the likelihood of variations in the final product. This is particularly important in industries such as electronics and semiconductors where uniformity is critical for the functionality of the product.

In addition to structural integrity and uniformity, preforming also allows for the optimization of material usage. By shaping the material to closely resemble the final product, it reduces the amount of material waste during subsequent processing stages. This not only contributes to cost savings but also aligns with sustainable manufacturing practices by minimizing material waste.

There are various techniques involved in the preforming process, each suited to different types of materials and end-products. For composites, processes such as draping, tape laying, and filament winding are commonly used to shape the fibers before they are further processed through techniques such as resin transfer molding or compression molding. In the case of metals, processes such as forging, extrusion, and rolling are used to shape the material before it undergoes further processing through techniques such as machining or welding.

Overall, preforming holds a significant role in the manufacturing process, contributing to the overall quality, functionality, and cost-effectiveness of the final product. Its ability to enhance structural integrity, achieve uniformity, and optimize material usage makes it an indispensable stage in the manufacturing process. As industries continue to push the boundaries of innovation and efficiency, the importance of preforming in manufacturing processes will only continue to grow.

- Benefits of Preforming in the Production Process

Preforming, also known as preform molding, plays a crucial role in the manufacturing process across various industries. This essential step involves shaping a raw material into a required form before it undergoes further processing. In this article, we will delve into the benefits of preforming in the production process, highlighting its importance and the advantages it offers.

One of the key benefits of preforming in the production process is the improvement in material properties. By preforming raw materials such as plastics, metals, and composites, manufacturers can enhance the material's strength, durability, and overall performance. This is achieved by aligning the molecular structure of the material, which results in a more uniform and consistent product. As a result, the end product exhibits superior mechanical properties, making it suitable for a wide range of applications.

In addition, preforming enables manufacturers to achieve complex shapes and geometries with precision and accuracy. This is particularly valuable in industries such as automotive, aerospace, and medical devices, where intricate and custom-designed components are required. Preforming allows for the creation of tailored shapes and sizes, which would be challenging to achieve through conventional manufacturing processes. This level of customization not only meets the specific requirements of the end product but also contributes to the overall efficiency of the manufacturing process.

Furthermore, preforming plays a vital role in reducing material waste and optimizing production costs. By shaping the raw material into a near-net shape during the preforming stage, manufacturers minimize the amount of material that is wasted during subsequent machining or forming processes. This not only reduces material costs but also contributes to a more sustainable and environmentally friendly manufacturing process. Additionally, the use of preforming can lead to increased production efficiency and reduced lead times, ultimately resulting in cost savings and improved competitiveness in the market.

Another significant advantage of preforming in the production process is the ability to control the material's microstructure and properties. Through precise control of temperature, pressure, and molding conditions, manufacturers can tailor the material's characteristics to meet specific performance requirements. This allows for the production of high-quality and consistent products that offer superior mechanical, thermal, and electrical properties. As a result, preforming enhances the overall quality and reliability of the end product, meeting the stringent demands of modern manufacturing standards.

Moreover, preforming facilitates the integration of additional features and functionalities into the material, such as inserts, reinforcements, and surface finishes. This flexibility allows manufacturers to create advanced and multifunctional components that meet diverse application needs. Whether it is adding conductive elements to improve electrical conductivity or incorporating reinforcing fibers to enhance structural integrity, preforming enables the creation of highly customized and value-added products.

In conclusion, the benefits of preforming in the production process are vast and varied, encompassing improvements in material properties, complex shape capabilities, cost reductions, and quality enhancements. By understanding the importance of preforming and its impact on the manufacturing process, industries can harness the full potential of this essential technique to elevate their products and stay ahead in the competitive market.

- Materials and Techniques Used in Preforming

Preforming is a crucial step in the manufacturing process that involves shaping raw materials into a desired form before further processing. This important stage can significantly impact the quality, efficiency, and consistency of the final product. In this article, we will explore the materials and techniques used in preforming and understand their importance in the manufacturing industry.

Materials used in preforming can vary depending on the specific requirements of the final product. Common materials include metals, plastics, ceramics, and composites. Each material has its own unique properties, and the choice of material for preforming is a critical decision that can affect the overall performance of the product. For example, metals are often preformed through processes such as forging or extrusion, while plastics may be preformed through injection molding or blow molding. Ceramics, on the other hand, may undergo preforming through techniques like slip casting or isostatic pressing.

The techniques used in preforming are equally diverse and can be classified into several categories. One common technique is forming, which involves manipulating the material into the desired shape through processes such as bending, stretching, or rolling. Another technique is molding, which utilizes molds to shape the material into the desired form. This can include processes like compression molding, transfer molding, or injection molding, depending on the material and product requirements. Additionally, preforming techniques can also involve additive manufacturing, where materials are built up layer by layer using 3D printing technology.

One important aspect of preforming is the consideration of the material’s behavior under various conditions. Understanding the material’s properties and how it responds to different forces and temperatures is crucial in determining the appropriate preforming techniques. For instance, metals may require specific temperatures and pressures to be formed effectively, while plastics may have different flow characteristics that need to be considered during preforming. Additionally, the choice of tooling and equipment can also significantly impact the preforming process, as it needs to be capable of handling the specific material and technique requirements.

In conclusion, preforming plays a critical role in the manufacturing process by shaping raw materials into the desired form before further processing. The choice of materials and techniques used in preforming can greatly influence the quality, efficiency, and consistency of the final product. Manufacturers must carefully consider the material properties, preforming techniques, and equipment requirements to ensure a successful preforming process. By understanding the importance of preforming and utilizing the appropriate materials and techniques, manufacturers can improve the overall production process and achieve superior results in the final product.

- Quality Control and Preforming in Manufacturing

Understanding the Importance of Preforming in Manufacturing Processes - Quality Control and Preforming in Manufacturing

In the world of manufacturing, preforming plays a crucial role in ensuring the quality and efficiency of the manufacturing processes. From plastics to metals to composites, preforming is utilized to shape raw materials into the desired form before the final manufacturing steps take place. This article aims to shed light on the importance of preforming in manufacturing processes, with a focus on quality control and its impact on the overall production.

Preforming is the process of shaping raw materials into a specific form or shape before the final manufacturing steps, such as molding or casting, take place. This preliminary step not only saves time and resources during the final manufacturing process, but it also ensures that the finished products meet the required specifications and quality standards. Quality control is an integral part of preforming, as it ensures that the preformed materials are free from defects and inconsistencies that could ultimately compromise the quality of the final product.

One of the key advantages of preforming in manufacturing processes is its ability to improve the overall efficiency and accuracy of the manufacturing process. By shaping the raw materials into the desired form beforehand, manufacturers can significantly reduce the time and resources required for the final manufacturing steps. This not only leads to cost savings, but also enhances the overall productivity of the manufacturing process.

Quality control plays a critical role in preforming, as it helps to identify any defects or inconsistencies in the preformed materials before they are further processed. Through meticulous inspection and testing, manufacturers can ensure that the preformed materials meet the required specifications and quality standards, thus minimizing the risk of defects in the final product. This proactive approach to quality control not only helps to maintain the integrity of the manufacturing process, but also minimizes the likelihood of costly rework or product recalls.

Furthermore, preforming in manufacturing processes also allows for greater design flexibility and customization. By shaping the raw materials into the desired form beforehand, manufacturers can easily incorporate intricate designs and complex geometries into the final product. This level of flexibility not only allows for greater design innovation, but also enhances the overall aesthetic appeal and functionality of the finished products.

In conclusion, preforming plays a crucial role in manufacturing processes, with quality control being a key component in ensuring the integrity and consistency of the preformed materials. Through preforming, manufacturers can improve the overall efficiency and accuracy of the manufacturing process, while also allowing for greater design flexibility and customization. By integrating quality control into the preforming process, manufacturers can ensure that the preformed materials meet the required specifications and quality standards, ultimately leading to high-quality finished products.

- Future Trends in Preforming Technology

In the rapidly evolving landscape of manufacturing, preforming technology is proving to be a crucial aspect of the production process. As advancements in material science and engineering continue to expand the possibilities in various industries, the importance of preforming in manufacturing processes cannot be understated. From aerospace to automotive, and from medical devices to consumer goods, the future trends in preforming technology are set to revolutionize the way products are made.

Preforming, in the context of manufacturing, refers to the process of shaping raw materials into a specific form before they are further processed. This preliminary step is essential in achieving the desired characteristics and properties of the final product. By preforming materials such as composites, metals, and polymers, manufacturers can control the orientation, thickness, and overall structure of the material, ultimately leading to a higher quality end product.

Looking towards the future, several trends are set to shape the landscape of preforming technology. One such trend is the increasing use of automation and robotics in preforming processes. As the demand for precision and efficiency continues to grow, automation technology is being integrated into preforming systems to streamline production and minimize human error. This not only results in higher quality products but also allows for greater flexibility in design and manufacturing.

Additionally, the development of new materials and composites is driving the future trends in preforming technology. With the ongoing pursuit of lightweight, high-strength materials, manufacturers are constantly exploring new combinations and formulations. As a result, preforming technology is adapting to accommodate the unique characteristics of these advanced materials, enabling the production of complex shapes and structures with unprecedented performance qualities.

Another significant trend in preforming technology is the rise of additive manufacturing, also known as 3D printing. While traditional preforming methods involve shaping materials through molding and forming processes, 3D printing allows for the direct fabrication of preforms with intricate geometries. This technology opens up new possibilities in design and production, particularly in industries where customization and rapid prototyping are paramount.

Furthermore, the integration of digital technologies such as artificial intelligence and advanced simulations is expected to play a crucial role in the future of preforming. By leveraging data-driven insights and predictive modeling, manufacturers can optimize their preforming processes and predict the behavior of materials with greater accuracy. This not only enhances the efficiency of production but also paves the way for innovation in material design and performance.

Overall, the future trends in preforming technology are driven by a combination of technological advancements, material innovations, and a growing demand for high-performance products. As the manufacturing industry continues to evolve, preforming technology will undoubtedly be at the forefront of these changes, shaping the way products are made and setting new standards for quality and efficiency. In order to stay competitive in the global market, manufacturers must embrace these trends and capitalize on the opportunities they present. The future of manufacturing is indeed being shaped by the advancements in preforming technology, and the potential for groundbreaking developments in the years to come is truly exciting.

Conclusion

In conclusion, it is clear that preforming plays a crucial role in manufacturing processes. From reducing material waste to improving overall production efficiency, the importance of preforming cannot be overstated. As a company with 4 years of experience in the industry, we have seen firsthand the impact that preforming can have on our manufacturing processes. By understanding and implementing preforming techniques, we have been able to streamline our operations and deliver high-quality products to our customers. Moving forward, we will continue to prioritize preforming in our manufacturing processes, recognizing its vital role in the success of our company.