Crafting High-Quality Pet Preform Molds: A Complete Guide

Welcome to our comprehensive guide on crafting high-quality pet preform molds! If you are looking to create durable, precise, and functional molds for your pet preform production, then you've come to the right place. In this article, we will walk you through the essential steps, tips, and best practices for crafting top-notch pet preform molds. Whether you are a novice in mold making or a seasoned professional, this guide will provide valuable insights to help you achieve outstanding results. So, let's dive in and explore the fascinating world of pet preform mold crafting!

- Understanding the Importance of High-Quality Pet Preform Molds

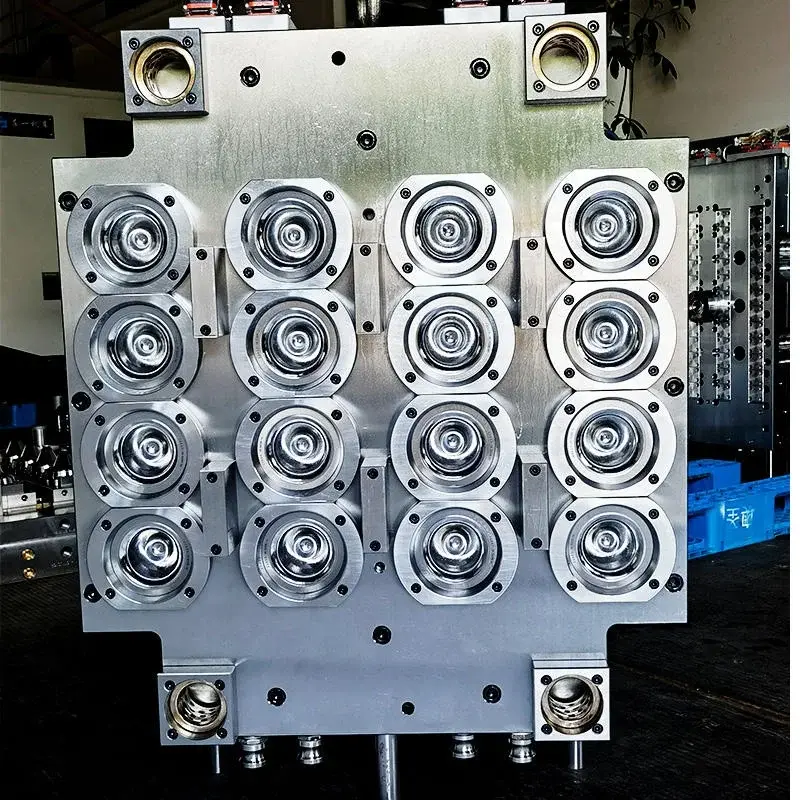

Pet preform molds play a crucial role in the production of high-quality pet preforms, which are used in the manufacturing of plastic bottles for various applications. Understanding the importance of high-quality pet preform molds is essential for businesses and manufacturers in the plastic packaging industry. In this complete guide, we will delve into the intricacies of crafting high-quality pet preform molds and the significance of their role in the production process.

First and foremost, it is imperative to understand the significance of pet preform molds in the plastic packaging industry. Pet preform molds are used to create preforms, which are then heated and stretched to form plastic bottles. These preforms need to be of the highest quality to ensure the structural integrity and functionality of the end product. As such, the quality of the pet preform mold directly impacts the quality of the final plastic bottle, making it an integral part of the production process.

Crafting high-quality pet preform molds requires precision and expertise. The design and manufacturing of these molds must adhere to strict standards to ensure optimal performance and durability. The material used in the construction of the mold is crucial, as it must be able to withstand high temperatures and pressures during the injection molding process. Additionally, the design of the mold must be meticulously engineered to produce consistent and accurate preforms.

The importance of high-quality pet preform molds extends beyond just the production process. These molds are an investment for manufacturers, and their durability and longevity directly impact the bottom line. A well-crafted mold will have a longer lifespan and require less maintenance, ultimately reducing production costs and maximizing efficiency. In contrast, a low-quality mold may lead to frequent breakdowns, production delays, and increased expenses.

Furthermore, the quality of the pet preform mold can also affect the overall sustainability of the manufacturing process. A high-quality mold is more likely to produce uniform and defect-free preforms, minimizing material waste and energy consumption. This is not only beneficial for the environment but also for the financial sustainability of the business.

In conclusion, the importance of high-quality pet preform molds cannot be understated in the plastic packaging industry. These molds are essential for producing consistent and high-quality preforms, which ultimately determine the quality of the final product. Crafting high-quality pet preform molds requires meticulous design and construction to ensure optimal performance and longevity. By investing in high-quality molds, manufacturers can improve the efficiency, sustainability, and profitability of their production processes.

- Key Factors to Consider in Crafting High-Quality Pet Preform Molds

Crafting High-Quality Pet Preform Molds: Key Factors to Consider in Crafting High-Quality Pet Preform Molds

When it comes to creating high-quality pet preform molds, there are a number of key factors that need to be considered in order to ensure a successful end product. In this article, we will explore the various factors that go into crafting high-quality pet preform molds, and discuss why each one is important in the overall process.

Material Selection

One of the most important factors to consider when crafting high-quality pet preform molds is the selection of materials. The materials used in the construction of the mold will have a significant impact on the final product, so it is essential to choose materials that are durable, heat-resistant, and able to maintain their shape over time. Common materials used for pet preform molds include stainless steel, aluminum, and various types of plastics.

Design and Engineering

The design and engineering of the pet preform mold are crucial in ensuring that the final product meets the necessary specifications. It is important to work with an experienced team of designers and engineers who understand the specific requirements of pet preform molds and can create a mold that meets these requirements. This includes factors such as the size and shape of the preform, the number of cavities in the mold, and the overall structure of the mold.

Precision and Accuracy

Another key factor to consider in crafting high-quality pet preform molds is precision and accuracy. The mold must be manufactured to extremely tight tolerances in order to produce high-quality preforms that meet the necessary specifications. This requires the use of advanced machining and manufacturing techniques to ensure that the mold is constructed with the utmost precision.

Quality Control

Quality control is an essential aspect of crafting high-quality pet preform molds. The mold must undergo rigorous testing and inspection to ensure that it meets the necessary standards for durability, accuracy, and performance. This includes testing the mold under various conditions to simulate real-world use and identifying any potential issues that need to be addressed.

Experience and Expertise

Crafting high-quality pet preform molds requires a high level of experience and expertise in the field of mold making. It is essential to work with a team of professionals who have a deep understanding of the materials, design, and engineering principles necessary to create a high-quality pet preform mold. This includes the ability to identify potential problems and address them effectively to ensure the final product meets the necessary standards.

Crafting high-quality pet preform molds is a complex and intricate process that requires careful consideration of a number of key factors. By paying close attention to material selection, design and engineering, precision and accuracy, quality control, and experience and expertise, it is possible to create a high-quality pet preform mold that meets the necessary standards for performance and durability. With the right team and the right approach, it is possible to create a pet preform mold that meets the highest standards of quality and reliability.

- Steps to Take in Designing and Building High-Quality Pet Preform Molds

Designing and building high-quality pet preform molds is a crucial step in the production of high-quality pet bottles. In this complete guide, we will explore the essential steps to take in crafting pet preform molds that meet the industry's standards.

Step 1: Understanding the Requirements of Pet Preform Molds

The first step in designing and building high-quality pet preform molds is to understand the specific requirements of the molds. These requirements can vary depending on the type of pet bottles being produced, the production volume, and the specific features to be incorporated into the molds.

Step 2: Designing the Mold

Once the requirements of the pet preform molds are clearly defined, the next step is to design the molds. This involves the use of advanced computer-aided design (CAD) software to create a 3D model of the mold. During the design phase, it is crucial to pay attention to the mold's geometry, cooling system, and other critical aspects that contribute to the mold's overall quality.

Step 3: Selecting the Right Materials

The selection of materials for pet preform molds is a critical step in ensuring their quality and longevity. High-quality steel, such as stainless steel or tool steel, is often used for the construction of pet preform molds due to its durability and resistance to wear and tear. Additionally, the choice of materials can also impact the mold's performance and the quality of the final pet bottles.

Step 4: Building the Mold

Once the design and material selection are finalized, the next step is to build the pet preform molds. This process involves the use of advanced machining techniques, such as CNC milling and turning, to fabricate the mold components to the precise specifications outlined in the design phase. The use of cutting-edge manufacturing technologies and precision tools is essential in ensuring the accuracy and quality of the mold components.

Step 5: Quality Control and Testing

After the pet preform molds are built, they undergo rigorous quality control and testing procedures to ensure their performance and reliability. This involves conducting thorough inspections of the mold components, checking for any defects or imperfections, and testing the molds under simulated production conditions to verify their functionality and performance.

Step 6: Fine-tuning and Optimization

Once the initial testing is completed, any necessary fine-tuning and optimization of the pet preform molds are carried out to address any potential issues or inefficiencies. This may involve making minor adjustments to the mold's design or cooling system to further improve its performance and quality.

In conclusion, designing and building high-quality pet preform molds is a complex and highly specialized process that requires expertise, precision, and attention to detail. By following the essential steps outlined in this guide, manufacturers can ensure that their pet preform molds meet the industry's standards and contribute to the production of top-quality pet bottles.

- Testing and Quality Control Measures for High-Quality Pet Preform Molds

Crafting High-Quality Pet Preform Molds: A Complete Guide

Pet preform molds are crucial in the production of high-quality pet products, such as bottles and containers. In order to ensure the quality and precision of these molds, thorough testing and quality control measures are imperative. This article will provide a comprehensive guide to the testing and quality control measures for high-quality pet preform molds.

One of the key aspects of ensuring the quality of pet preform molds is thorough testing. This involves various testing procedures to check for the accuracy and durability of the molds. The first step in testing is dimensional accuracy, which involves ensuring that the dimensions of the mold are precise and consistent. This is essential in producing uniform pet preforms that meet the required specifications.

Another important aspect of testing is material testing. This involves testing the materials used in the mold to ensure that they are of high quality and suitable for the production of pet preforms. The material used in the mold should be durable and resistant to wear and tear, as it will undergo continuous use during the production process.

In addition to material testing, it is also important to conduct functional testing of the pet preform molds. This involves testing the functionality of the mold, including its ability to produce accurate and consistent pet preforms. Functional testing also includes checking for any defects or malfunctions in the mold that may affect the quality of the pet preforms.

Quality control measures are also essential in ensuring the high quality of pet preform molds. This involves implementing strict quality control processes throughout the production of the molds. This includes monitoring the manufacturing process and conducting regular inspections to identify any potential issues or defects in the molds.

One of the key quality control measures for pet preform molds is mold maintenance. Regular maintenance of the molds is essential in ensuring their longevity and performance. This includes cleaning the molds, inspecting for any wear and tear, and making any necessary repairs or replacements. Proper maintenance of the molds will not only ensure their quality but also prolong their lifespan, ultimately saving costs for the manufacturer.

Another important quality control measure is the implementation of quality management systems. These systems include documenting the production process, monitoring and analyzing data, and implementing corrective actions when necessary. Quality management systems help to identify any issues or inconsistencies in the production process, allowing for prompt resolution and maintaining the high quality of the pet preform molds.

In conclusion, thorough testing and quality control measures are vital in ensuring the high quality of pet preform molds. By implementing rigorous testing procedures and quality control measures, manufacturers can guarantee the accuracy, durability, and functionality of their molds, ultimately leading to the production of high-quality pet preforms. This complete guide provides valuable insights into the testing and quality control measures necessary for crafting high-quality pet preform molds.

- Maintenance and Care Tips for Ensuring High-Quality Pet Preform Molds

Pet preform molds are essential tools in the manufacturing of pet preforms, which are later used to produce various types of plastic containers and bottles. In order to ensure high-quality pet preforms and the overall efficiency of the production process, it is crucial to provide regular maintenance and care for the molds. This article will provide a complete guide on how to effectively maintain and care for pet preform molds, ensuring their high quality and longevity.

First and foremost, it is important to understand the significance of maintaining pet preform molds. These molds are subjected to high pressure and temperature during the production process, which can lead to wear and tear over time. Without proper maintenance, the quality of the pet preforms can be compromised, leading to defects and inconsistencies in the final products. Regular maintenance and care not only prolong the lifespan of the molds but also contribute to the overall efficiency and quality of the production process.

One of the key maintenance practices for pet preform molds is regular cleaning. As the molds come into contact with various types of materials and substances during the production process, it is important to clean them thoroughly to prevent the accumulation of dirt, debris, and other contaminants. This can be done using specialized cleaning solutions and equipment, ensuring that the molds are free from any residues that may affect the quality of the pet preforms.

In addition to cleaning, it is also crucial to inspect the molds regularly for any signs of wear and damage. This includes checking for cracks, worn-out components, and other issues that may arise from the high pressures and temperatures involved in the production process. Identifying and addressing these issues early on can prevent further damage to the molds and ensure the consistent quality of the pet preforms.

Furthermore, maintaining the proper temperature and pressure settings during the production process is essential for extending the lifespan of pet preform molds. Excessive heat and pressure can lead to premature wear and damage, while insufficient settings can result in subpar quality pet preforms. It is therefore important to monitor and regulate these factors to ensure that the molds are operating at their optimal conditions.

In addition to regular maintenance practices, it is also important to store pet preform molds properly when they are not in use. This includes storing them in a clean and controlled environment, protecting them from dust, moisture, and other potential contaminants. Proper storage can prevent unnecessary wear and damage to the molds, prolonging their lifespan and maintaining their high quality.

In conclusion, the maintenance and care of pet preform molds are crucial for ensuring the high quality and longevity of these essential tools in the production process. By implementing regular cleaning, inspections, and proper storage practices, manufacturers can maximize the efficiency and consistency of their pet preform production while prolonging the lifespan of their molds. Investing in the maintenance and care of pet preform molds is an investment in the overall quality and success of the manufacturing process.

Conclusion

In conclusion, crafting high-quality pet preform molds requires a deep understanding of the materials, processes, and industry standards. With over four years of experience in the industry, our company is well-equipped to meet the demands of pet preform mold production. By following the complete guide provided in this article, manufacturers can ensure that their molds meet the highest standards of quality and precision. With attention to detail and a commitment to excellence, companies can produce pet preform molds that meet the needs of the ever-growing pet industry. As we continue to refine our processes and techniques, we look forward to providing even more advanced solutions in the years to come. Thank you for reading, and we hope this guide has been a valuable resource for your pet preform mold crafting needs.