Understanding The Importance Of Pet Bottle Preforms In Packaging Industry

Welcome to our article on the importance of pet bottle preforms in the packaging industry. As consumers, we often take for granted the intricacies of the packaging process, but pet bottle preforms play a crucial role in creating the products we use every day. In this article, we will delve into the significance of pet bottle preforms and how they impact the packaging industry. Whether you are a packaging industry professional or simply interested in learning more about the products we use, this article will provide valuable insights into the role of pet bottle preforms in the packaging process. Join us as we explore the essential role of pet bottle preforms in the packaging industry.

The Role of Pet Bottle Preforms in Packaging Industry

The packaging industry plays a crucial role in the global economy, as it is responsible for ensuring the safe and efficient transportation of goods. Within the packaging industry, pet bottle preforms are a vital component that significantly impacts the manufacturing and distribution processes of various products. In this article, we will explore the role of pet bottle preforms in the packaging industry, highlighting their importance and relevance in today's market.

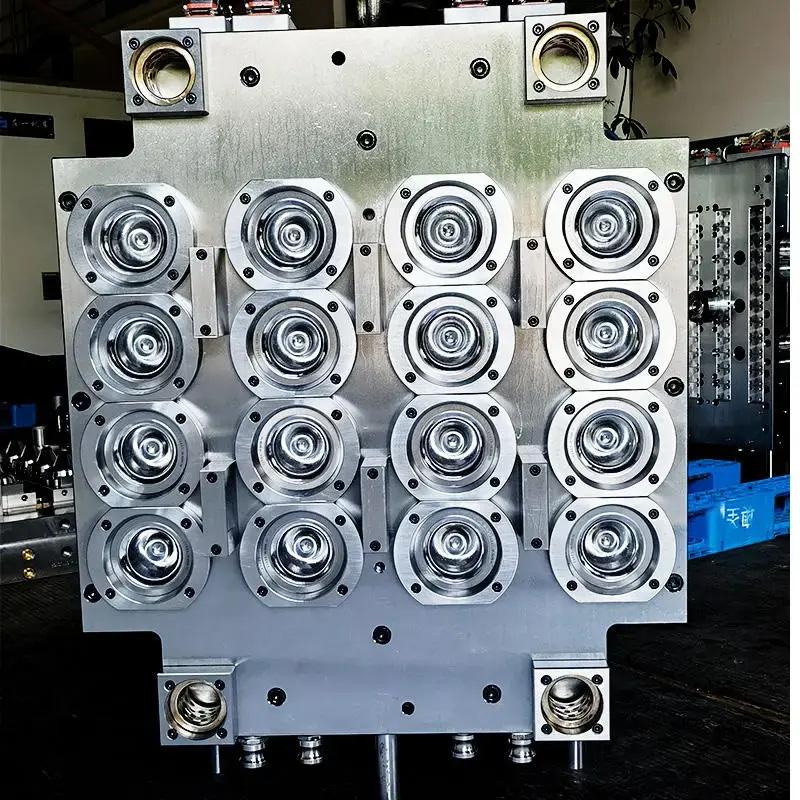

Pet bottle preforms, also known as PET preforms, are semi-finished products that are used in the production of plastic bottles and containers. These preforms are typically made from polyethylene terephthalate (PET) resin and are manufactured using a process called injection molding. The pet bottle preform serves as the initial form of the bottle, which is later blown into its final shape using a stretch blow molding process. This versatile and cost-effective manufacturing method has made pet bottle preforms an essential component in the packaging industry.

One of the key advantages of using pet bottle preforms in packaging is their lightweight and durable nature. PET resin is known for its strength and rigidity, making it an ideal material for packaging applications. Additionally, pet bottle preforms are transparent, allowing for the clear display of the packaged product, which is particularly important in industries such as food and beverages.

Due to their versatility, pet bottle preforms are used in a wide range of industries, including the beverage, pharmaceutical, personal care, and household product sectors. The use of pet bottle preforms in these industries has revolutionized the packaging of various products, offering a cost-effective and sustainable solution for manufacturers.

In recent years, there has been a growing demand for sustainable packaging solutions, driven by consumer awareness and environmental concerns. Pet bottle preforms have played a significant role in meeting this demand, as PET resin is fully recyclable and can be repurposed into new products. This makes pet bottle preforms an environmentally friendly choice for manufacturers looking to minimize their carbon footprint and reduce waste.

Furthermore, pet bottle preforms have also contributed to the development of innovative packaging designs and shapes. With advancements in technology and manufacturing processes, manufacturers can produce custom-designed pet bottle preforms to meet specific packaging requirements. This flexibility has allowed for the creation of unique and eye-catching packaging solutions that help products stand out on the shelves.

In conclusion, the role of pet bottle preforms in the packaging industry cannot be overstated. From their lightweight and durable properties to their versatility and sustainability, pet bottle preforms have become an integral part of modern packaging solutions. As the demand for innovative and eco-friendly packaging continues to grow, pet bottle preforms will undoubtedly remain a driving force in shaping the future of the packaging industry.

The Importance of Quality and Design in Pet Bottle Preforms

The packaging industry plays a critical role in ensuring the safe and efficient delivery of products to consumers. Within this industry, pet bottle preforms are a crucial component in the production of plastic bottles, serving as the foundation for the final packaging. The quality and design of these preforms are of utmost importance, as they directly impact the overall performance and integrity of the final product.

When it comes to pet bottle preforms, quality is non-negotiable. These preforms are responsible for holding and protecting the contents of the bottle, whether it be water, soda, juice, or other beverages. As such, any compromise in the quality of the preforms can result in leakage, breakage, or contamination of the product, leading to customer dissatisfaction and potential financial losses for the manufacturer.

One of the key aspects of quality in pet bottle preforms is their ability to withstand pressure. In industries such as carbonated beverages, the preforms must be able to withstand the internal pressure created by the carbonation process without deforming or bursting. This requires meticulous design and precise manufacturing to ensure the preforms meet the necessary strength requirements.

Furthermore, the design of pet bottle preforms plays a significant role in the overall packaging. The shape, size, and weight of the preform directly influence the appearance and functionality of the final bottle. A well-designed preform will not only make the production process more efficient but also result in a visually appealing and user-friendly end product.

For manufacturers, investing in high-quality and well-designed pet bottle preforms can yield numerous benefits. Firstly, it minimizes the risk of product recalls and customer complaints, thereby safeguarding the brand's reputation and credibility. Additionally, it enhances the overall production efficiency, reducing waste and costs associated with defective preforms.

Moreover, from a sustainability standpoint, the design of pet bottle preforms can contribute to reducing the environmental impact of plastic packaging. Lightweight designs and optimized shapes can result in lower material usage, leading to reduced carbon footprint and resource conservation.

In conclusion, the importance of quality and design in pet bottle preforms cannot be overstated. As a critical component in the packaging industry, the performance and integrity of these preforms directly impact the safety, functionality, and sustainability of the final product. By prioritizing quality and design in pet bottle preforms, manufacturers can ensure a superior end product and contribute to a more sustainable and efficient packaging industry.

Cost-Effectiveness and Efficiency of Pet Bottle Preforms

When it comes to the packaging industry, cost-effectiveness and efficiency are two crucial factors that companies must consider. As such, understanding the importance of PET bottle preforms is essential for any business involved in the production and distribution of bottled products. In this article, we will delve into the significance of PET bottle preforms in the packaging industry, focusing on their cost-effectiveness and efficiency.

PET bottle preforms are essentially the starting point of any PET bottle production. These preforms are usually made from PET resin and are shaped like a test tube with a threaded neck. They are then heated and stretched into the desired shape of the bottle. PET bottle preforms are crucial in the packaging industry as they form the foundation for the final product, and play a significant role in determining the cost-effectiveness and efficiency of the entire packaging process.

Cost-effectiveness is one of the primary advantages of using PET bottle preforms in the packaging industry. PET resin, the primary material used to make these preforms, is relatively inexpensive compared to other plastics. This cost advantage is passed down the production line, resulting in lower overall production costs. Moreover, PET bottle preforms are lightweight, which means they require less material to produce, reducing both material costs and transportation costs. Additionally, PET bottle preforms are highly recyclable, making them an environmentally friendly and sustainable packaging option. This makes them a cost-effective choice in the long run, as they reduce waste and contribute to a company's sustainability efforts.

Efficiency is another critical aspect of PET bottle preforms in the packaging industry. The production process for these preforms is highly efficient, with the ability to produce a large number of preforms in a short period. This allows for faster and more streamlined production lines, reducing overall production time and increasing output. Furthermore, PET bottle preforms have a longer shelf life compared to other packaging materials, which means companies can stock up on preforms without worrying about their quality deteriorating over time. This results in more efficient inventory management and ensures a constant supply of preforms for production.

In addition to cost-effectiveness and efficiency, PET bottle preforms offer other benefits to the packaging industry. They are highly versatile and can be molded into various shapes and sizes to accommodate different bottle designs. This versatility allows for greater creativity and customization in packaging, providing companies with the opportunity to differentiate their products from competitors. Furthermore, PET bottle preforms have excellent barrier properties, ensuring that the packaged products are protected from external elements such as moisture and oxygen.

In conclusion, the importance of PET bottle preforms in the packaging industry cannot be overstated. Their cost-effectiveness and efficiency make them a top choice for companies seeking to optimize their packaging processes. Not only do they offer economic advantages, but they also contribute to sustainable and environmentally friendly packaging practices. As the demand for bottled products continues to rise, the significance of PET bottle preforms in the packaging industry will only continue to grow.

Environmental Impact and Sustainability of Pet Bottle Preforms

In recent years, the packaging industry has seen a major shift towards the use of pet bottle preforms as a sustainable alternative for packaging various products. These preforms have not only revolutionized the way products are packaged but have also contributed to reducing the environmental impact of packaging materials. Understanding the importance of pet bottle preforms in the packaging industry is crucial for businesses and consumers alike, as it sheds light on the environmental impact and sustainability of these innovative products.

One of the key factors that make pet bottle preforms essential in the packaging industry is their environmental impact. Traditional packaging materials such as glass and metal have a significant environmental footprint, as they require a large amount of energy and resources to manufacture and transport. On the other hand, pet bottle preforms are made from polyethylene terephthalate (PET), which is a lightweight and recyclable material. This makes them a more sustainable option, as they require less energy and resources to produce and can be recycled multiple times without compromising their quality.

Furthermore, the use of pet bottle preforms also contributes to the reduction of waste and pollution. With the increasing concern over plastic pollution, pet bottle preforms offer a viable solution by promoting recycling and reducing the amount of plastic waste ending up in landfills and oceans. By encouraging the use of recycled PET in the production of preforms, the packaging industry can further minimize its environmental impact and support the circular economy.

In addition to their environmental impact, pet bottle preforms also play a crucial role in promoting sustainability in the packaging industry. Their lightweight and durable nature make them an ideal choice for packaging various products, including beverages, personal care items, and household products. The use of preforms not only reduces the amount of packaging material required but also lowers the overall carbon footprint of the products being packaged. This aligns with the growing demand for sustainable packaging solutions that prioritize resource efficiency and environmental responsibility.

Moreover, the versatility of pet bottle preforms makes them a preferred choice for manufacturers and consumers. These preforms can be easily customized to create a wide range of bottle designs, shapes, and sizes, catering to the diverse needs of different industries and consumers. This flexibility not only enhances the visual appeal of the packaged products but also allows for efficient storage and transportation, further optimizing the overall sustainability of the packaging process.

In conclusion, the importance of pet bottle preforms in the packaging industry cannot be overstated. Their environmental impact and sustainability make them a valuable asset for businesses looking to reduce their carbon footprint and meet the growing demand for eco-friendly packaging solutions. By understanding the significance of pet bottle preforms, businesses and consumers can make informed decisions that support environmental responsibility and contribute to a more sustainable future.

Future Trends and Innovations in Pet Bottle Preforms Technology

The packaging industry has been evolving rapidly over the years, with a focus on efficiency, sustainability, and innovation. One of the key components of the packaging industry is pet bottle preforms, which play a crucial role in the production of pet bottles. These preforms are essentially the starting point for creating pet bottles and are an essential part of the packaging process.

As the demand for sustainable packaging solutions continues to grow, the future trends and innovations in pet bottle preforms technology are becoming increasingly important. Manufacturers in the packaging industry are constantly looking for ways to improve the production of pet bottle preforms to meet the changing needs of consumers and the environment.

One of the key future trends in pet bottle preforms technology is the use of recycled materials. With the increasing awareness of environmental issues, there is a growing demand for sustainable packaging solutions. Manufacturers are exploring ways to incorporate recycled materials into the production of pet bottle preforms, reducing the environmental impact of the packaging industry. This trend not only reduces the consumption of new raw materials but also helps in reducing the amount of waste generated.

Another important trend in pet bottle preforms technology is the development of lightweight preforms. As consumers become more conscious of their environmental footprint, there is a growing demand for lighter packaging materials. Manufacturers are investing in research and development to create lightweight pet bottle preforms that not only reduce the amount of plastic used but also lower transportation costs and energy consumption during production.

Furthermore, advancements in technology are leading to the development of innovative designs and shapes for pet bottle preforms. With advancements in 3D printing and molding technologies, manufacturers are able to create preforms in unique shapes and sizes, allowing for more creative and customized packaging solutions. This trend opens up new opportunities for branding and marketing, as companies can differentiate their products through unique packaging designs.

In addition to these trends, the incorporation of smart technology in pet bottle preforms is also on the rise. Smart packaging solutions, such as incorporating QR codes or RFID tags in preforms, enable manufacturers to track and trace products throughout the supply chain. This not only enhances the security and authenticity of the products but also provides valuable data for inventory management and consumer engagement.

In conclusion, pet bottle preforms play a critical role in the packaging industry, and the future trends and innovations in pet bottle preforms technology are essential for addressing the changing needs of the market. With a focus on sustainability, efficiency, and innovation, manufacturers are constantly striving to improve the production of pet bottle preforms to meet the evolving demands of consumers and the environment. As technology continues to advance, the future of pet bottle preforms looks promising, with a focus on sustainable materials, lightweight designs, innovative shapes, and smart technology integration.

Conclusion

In conclusion, the importance of pet bottle preforms in the packaging industry cannot be overstated. These preforms play a crucial role in ensuring the durability, safety, and convenience of packaging for various products. As a company with 4 years of experience in the industry, we understand the significance of using high-quality pet bottle preforms to meet the needs of our clients and their consumers. By prioritizing the use of reliable and efficient preforms, we continue to contribute to the overall success and growth of the packaging industry. Moving forward, we are committed to staying at the forefront of innovation and sustainability in order to provide the best packaging solutions for our clients.