Understanding The Importance Of Pet Bottle Preform In The Packaging Industry

Welcome to our latest article discussing the importance of pet bottle preform in the packaging industry. As consumers, we often overlook the significance of a pet bottle preform, but it plays a crucial role in ensuring the safety, quality, and sustainability of the products we use every day. Join us as we delve into the intricate world of pet bottle preforms and discover why they are essential to the packaging industry. Whether you are a consumer, manufacturer, or packaging professional, this article will provide valuable insights into the impact of pet bottle preforms on the products we use and the environment.

- Introduction to Pet Bottle Preform

to Pet Bottle Preform

In today’s modern world, the packaging industry plays a crucial role in protecting and preserving various products. One of the key components in the packaging industry is the pet bottle preform, a vital element in the production of plastic bottles. This article will provide a comprehensive overview of pet bottle preform, including its significance in the packaging industry, its manufacturing process, and its importance in ensuring quality and efficiency in packaging.

Pet bottle preforms are essentially the starting point in the production of plastic bottles. These preforms are typically made from polyethylene terephthalate (PET), a versatile and durable plastic material that is widely used for packaging purposes. The pet bottle preform is a test tube-shaped piece of plastic that is heated and stretched to form a bottle. But why is it so important in the packaging industry?

The importance of pet bottle preforms lies in their role as the foundation for plastic bottles. Without them, the production of plastic bottles would not be possible. Once the preforms are heated and stretched, they are then blown into the desired bottle shape. This crucial step in the manufacturing process demonstrates the significance of pet bottle preforms in creating a wide range of packaging solutions for various industries.

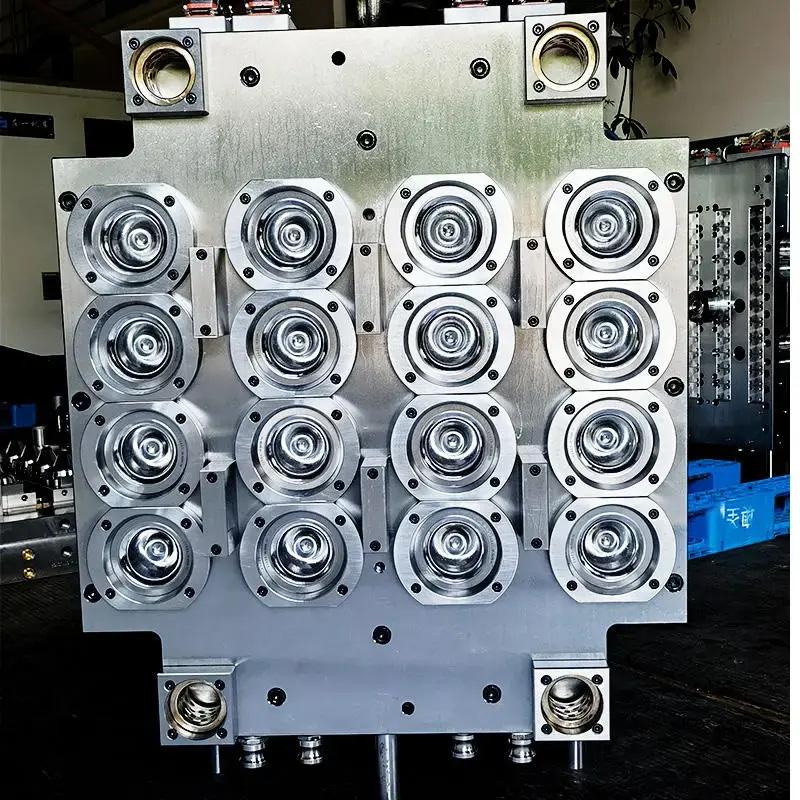

The manufacturing process of pet bottle preforms is a precise and carefully controlled operation. It begins with the extrusion of PET resin, which is melted and formed into a test tube shape. The preforms are then cooled and stored for future use. When the time comes for bottle production, the preforms are heated and stretched using specialized machines to create the desired bottle shape. This process requires high precision and expertise to ensure the quality and consistency of the preforms.

In addition to its role in bottle production, pet bottle preforms also play a significant role in ensuring the safety and integrity of the packaged products. The quality of the preforms directly impacts the quality and performance of the final plastic bottles. Therefore, it is essential for manufacturers to adhere to strict quality control measures during the production of pet bottle preforms to meet the industry standards and requirements.

Furthermore, pet bottle preforms are designed to meet the specific needs and preferences of consumers and industries. These preforms come in various shapes, sizes, and colors to accommodate different packaging requirements. Whether it’s for carbonated beverages, water, or personal care products, pet bottle preforms are versatile and adaptable to meet the diverse demands of the packaging industry.

In conclusion, pet bottle preforms are an essential component of the packaging industry. Their significance lies in their role as the foundation for plastic bottles, as well as their contribution to ensuring the quality and efficiency of packaging solutions. The manufacturing process of pet bottle preforms requires precision and expertise to produce high-quality preforms that meet industry standards. With their versatility and adaptability, pet bottle preforms continue to be a vital element in the packaging industry, serving as the starting point for innovative and sustainable packaging solutions.

- The Significance of Pet Bottle Preform in Packaging

Pet bottle preforms play a crucial role in the packaging industry, serving as the foundation for the creation of various types of plastic bottles. These preforms are of significant importance as they determine the shape, size, and quality of the final bottle, making them essential for manufacturers and consumers alike.

The significance of pet bottle preforms in the packaging industry is multifaceted, with numerous factors contributing to their importance. One of the primary reasons for their significance is their versatility. Pet bottle preforms can be used to create a wide range of bottle shapes and sizes, making them suitable for diverse packaging needs. From small, single-serve containers to large, multi-liter bottles, pet bottle preforms are adaptable to meet the demands of various industries, including food and beverage, personal care, pharmaceuticals, and more.

Additionally, the use of pet bottle preforms in packaging offers several advantages, such as lightweight and durable characteristics. These preforms are made of polyethylene terephthalate (PET), a lightweight yet robust material that is ideal for packaging applications. PET bottles are shatter-resistant, making them a safer alternative to glass bottles, especially for products that require transportation and handling.

Furthermore, the cost-effectiveness of pet bottle preforms is another significant factor in their importance. As the initial stage in the production of PET bottles, preforms are a cost-efficient option for manufacturers. Their lightweight nature also contributes to reduced transportation costs, making them an economically viable choice for packaging products. Additionally, the recyclability of PET material further enhances the cost-effectiveness of pet bottle preforms, as they can be recycled and reused in the production of new bottles, contributing to sustainability efforts.

In recent years, the demand for sustainable packaging solutions has propelled the importance of pet bottle preforms even further. As consumers become more conscious of environmental issues, there is a growing preference for eco-friendly packaging options. PET material, used in the production of bottle preforms, is recyclable and can be repurposed into a variety of products, including new bottles, apparel, and more. This sustainable aspect of PET bottles aligns with the trending consumer preference for environmentally-friendly packaging, further highlighting the significance of pet bottle preforms in the industry.

In conclusion, pet bottle preforms are an integral component of the packaging industry, with their versatility, cost-effectiveness, and sustainability making them a valuable asset for manufacturers and consumers alike. As the foundation for PET bottles, preforms play a crucial role in shaping the packaging landscape, offering a wide range of benefits and addressing the evolving needs of the industry. With the increasing demand for sustainable packaging solutions, the importance of pet bottle preforms is likely to continue growing, driving innovation and advancement in the packaging sector.

- Advantages of Using Pet Bottle Preform in Packaging

Pet bottle preform refers to the semi-finished form of a plastic bottle that is shaped like a test tube. It is widely used in the packaging industry for various products, including water, soda, juice, and other beverages. In recent years, the use of pet bottle preform has become increasingly popular due to its numerous advantages over other packaging materials. In this article, we will explore the importance of pet bottle preform in the packaging industry and the advantages it offers.

One of the key advantages of using pet bottle preform in packaging is its lightweight nature. This makes it easier and more cost-effective to transport and distribute products. Compared to glass or metal packaging, pet bottle preform reduces shipping costs and fuel consumption, making it a more environmentally friendly option. Additionally, the lightweight nature of pet bottle preform makes it easier for consumers to handle and transport their purchases.

Another significant advantage of pet bottle preform is its durability. PET (Polyethylene terephthalate) is a strong and resilient material that is able to withstand various external factors, such as temperature changes and pressure. This makes it an ideal choice for packaging products that require a long shelf life, such as carbonated drinks or bottled water. The durability of pet bottle preform also reduces the risk of product damage during transportation and storage, ultimately saving companies money on potential product losses.

Moreover, pet bottle preform is highly versatile and can be easily customized to suit the specific needs of different products. It can be molded into various shapes and sizes, allowing for unique and innovative packaging designs. This flexibility makes pet bottle preform a popular choice for brands looking to differentiate their products and stand out on the shelves. Additionally, pet bottle preform can be easily combined with different types of closures and labels, further enhancing its adaptability for different packaging requirements.

In addition to its versatility, pet bottle preform is also recyclable, making it an environmentally sustainable packaging solution. PET is a widely recycled material, and the use of recycled pet bottle preforms helps reduce the consumption of raw materials and minimizes waste. By encouraging the use of recycled pet bottle preform, companies can contribute to the circular economy and reduce their environmental footprint.

Furthermore, pet bottle preform is cost-effective and offers businesses a competitive edge in the market. Its production process is efficient and requires less energy compared to other packaging materials, resulting in lower manufacturing costs. Additionally, the lightweight nature of pet bottle preform reduces transportation expenses, contributing to overall cost savings. With its numerous advantages, pet bottle preform not only benefits businesses in terms of cost but also in terms of consumer satisfaction and brand reputation.

In conclusion, the importance of pet bottle preform in the packaging industry cannot be overstated. Its lightweight nature, durability, versatility, recyclability, and cost-effectiveness make it a highly desirable packaging material for a wide range of products. As businesses continue to prioritize sustainability and cost-efficiency, pet bottle preform remains a top choice for packaging solutions. By understanding the significance and advantages of pet bottle preform, companies can make informed decisions that benefit both their bottom line and the environment.

- Innovation and Future Trends in Pet Bottle Preform

The packaging industry is constantly evolving, and one of the key components in this evolution is the innovation and future trends in pet bottle preform. Pet bottle preforms are a crucial element in the production of PET (polyethylene terephthalate) bottles, which are widely used for packaging beverages, personal care products, pharmaceuticals, and more. Understanding the importance of pet bottle preform in the packaging industry is essential for manufacturers, suppliers, and consumers alike.

In recent years, there has been a significant focus on innovation in pet bottle preform production. This has been driven by the need for more sustainable packaging solutions, as well as the demand for greater efficiency and cost-effectiveness in manufacturing processes. One of the key innovations in pet bottle preform production is the development of advanced manufacturing techniques that allow for the production of preforms with a higher level of precision and consistency. This has resulted in the production of pet bottles that are stronger, lighter, and more environmentally friendly.

Another important trend in pet bottle preform production is the incorporation of recycled materials. As the demand for sustainable packaging solutions continues to grow, manufacturers are looking for ways to reduce their environmental impact. By using recycled materials in the production of pet bottle preforms, manufacturers can reduce the amount of virgin plastic used, while also diverting plastic waste from landfills. This trend is expected to continue to gain momentum in the coming years, as more and more consumers prioritize environmentally friendly packaging options.

In addition to sustainability, the future of pet bottle preform production is also likely to be shaped by advancements in material science and technology. Researchers and manufacturers are constantly exploring new materials and manufacturing processes that can improve the performance and properties of pet bottle preforms. This includes the development of barrier technologies that can extend the shelf life of packaged products, as well as the use of additives and coatings that can enhance the strength and durability of pet bottles.

Furthermore, the use of digital technologies, such as 3D printing and artificial intelligence, is also expected to play a significant role in the future of pet bottle preform production. These technologies have the potential to revolutionize the way pet bottle preforms are designed and manufactured, allowing for greater customization and innovation in packaging solutions.

Overall, the innovation and future trends in pet bottle preform are essential for the packaging industry. By focusing on sustainability, material science, and technology, manufacturers and suppliers can develop pet bottle preforms that not only meet the needs of consumers, but also contribute to a more sustainable and efficient packaging industry. As the demand for innovative and environmentally friendly packaging solutions continues to grow, the importance of pet bottle preform in the packaging industry will only continue to increase.

- Conclusion: The Integral Role of Pet Bottle Preform in the Packaging Industry

The packaging industry plays a crucial role in ensuring that products are protected, preserved, and presented to consumers in the best possible way. Within this industry, pet bottle preforms have become an integral component, serving as the foundation for the production of PET (polyethylene terephthalate) bottles, which are widely used for packaging beverages, food, personal care products, and more. Understanding the importance of pet bottle preforms in the packaging industry is essential for all stakeholders involved, from manufacturers to consumers.

Pet bottle preforms are essentially the starting point for the production of PET bottles. These preforms are typically made using injection molding machines, which heat and inject PET resin into a mold to create the desired shape and size. Once the preforms have been produced, they are then heated and stretched in a blow molding machine to form the final PET bottles.

One of the key reasons for the widespread use of pet bottle preforms in the packaging industry is their versatility. These preforms can be customized to create bottles of various shapes, sizes, and neck finishes, making them suitable for a wide range of products. Additionally, PET is a lightweight and durable material, making it ideal for packaging applications.

The use of pet bottle preforms also offers several advantages from a manufacturing perspective. The production process for pet bottle preforms is relatively cost-effective, and the lightweight nature of PET bottles reduces shipping costs and environmental impact. Furthermore, PET is a fully recyclable material, aligning with the growing emphasis on sustainability within the packaging industry.

In addition to their practical advantages, pet bottle preforms also play a crucial role in maintaining product integrity. PET is non-reactive and has excellent barrier properties, providing a protective environment for the products inside the bottles. This is particularly important for beverages and food products, as it helps to preserve freshness and quality.

For consumers, the use of PET bottles made from pet bottle preforms offers convenience and safety. PET bottles are lightweight and are less likely to break or shatter compared to glass containers. They are also widely accepted for recycling, promoting environmental responsibility.

Looking ahead, the role of pet bottle preforms in the packaging industry is likely to remain essential. As the demand for PET bottles continues to grow across various sectors, manufacturers will continue to rely on pet bottle preforms as the building blocks for their packaging solutions. With ongoing advancements in technology and sustainability initiatives, the production and use of pet bottle preforms are expected to become even more efficient and environmentally friendly.

In conclusion, pet bottle preforms are a fundamental aspect of the packaging industry, serving as the basis for the production of PET bottles. Their versatility, cost-effectiveness, protective properties, and sustainability make them a valuable asset for manufacturers and consumers alike. As the packaging industry continues to evolve, pet bottle preforms will undoubtedly remain a crucial element in meeting the demands of modern packaging solutions.

Conclusion

In conclusion, the importance of pet bottle preforms in the packaging industry cannot be overstated. These preforms play a crucial role in ensuring the safety, quality, and shelf-life of various products, making them a vital component in the packaging process. As a company with 4 years of experience in the industry, we understand the significance of using high-quality pet bottle preforms and are committed to providing our customers with the best options available. By recognizing the importance of pet bottle preforms, we can continue to innovate and improve our packaging solutions, ultimately benefiting both our clients and the end consumers. With our dedication to understanding and utilizing the best pet bottle preforms, we look forward to continuing to make a positive impact in the packaging industry.