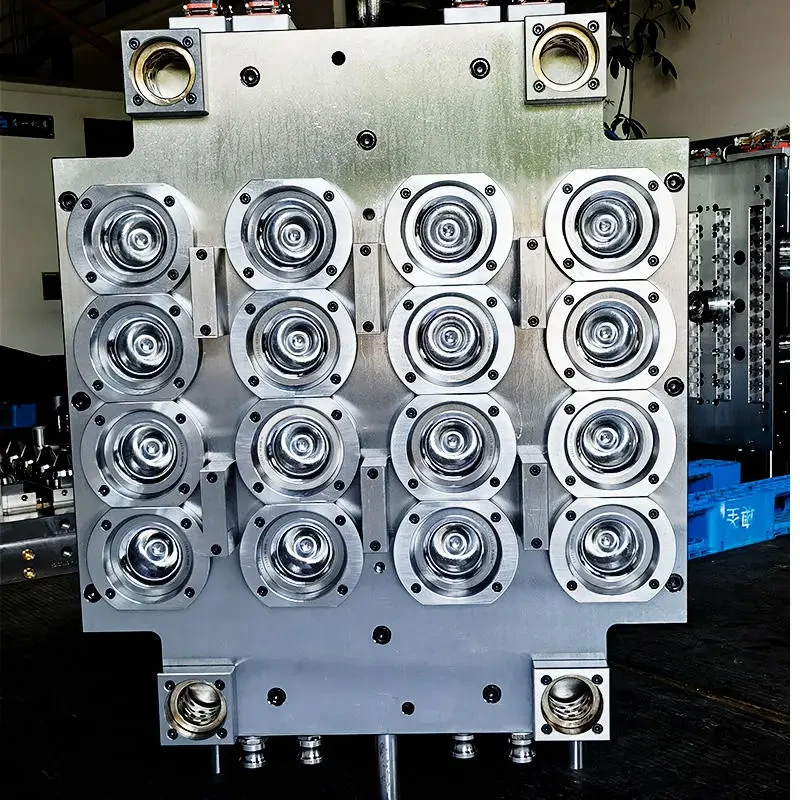

1: The number of preform cavity from 1 to 96.

2: The bottle preform is designed by computer simulation tensile test to improve the finished product rate of the

blown bottle.

blown bottle.

3: Adopt the world advanced two-level double-taper positioning technology, each cavity is self-locked independently,

to ensure the concentricity of the mold.

to ensure the concentricity of the mold.

4: Mold injection cavity and injection core are made of high quality preheating special die steel from the original Factory in Sweden.

5: Thread mouth according to international standard manufacturing, the material selection of imported nitriding, high hardness, long service life.

6: Advanced design of hot runner, uniform heating temperature,improve the quality of plastic products.

7: no shear gate, reduce the labor intensity of workers.

8: Mold life is guaranteed to be more than 3 million mold times.